Our Capabilities in Product Development

Product development refers to the complete process of conceptualizing, planning, researching, strategizing, sketching, designing, prototyping, and manufacturing a product that is ready for the market. This involves utilizing a range of services, including industrial design and mechanical engineering services, especially during the initial stages of product development. The end goal is to transform a conceptual idea into a functional, market-ready product.

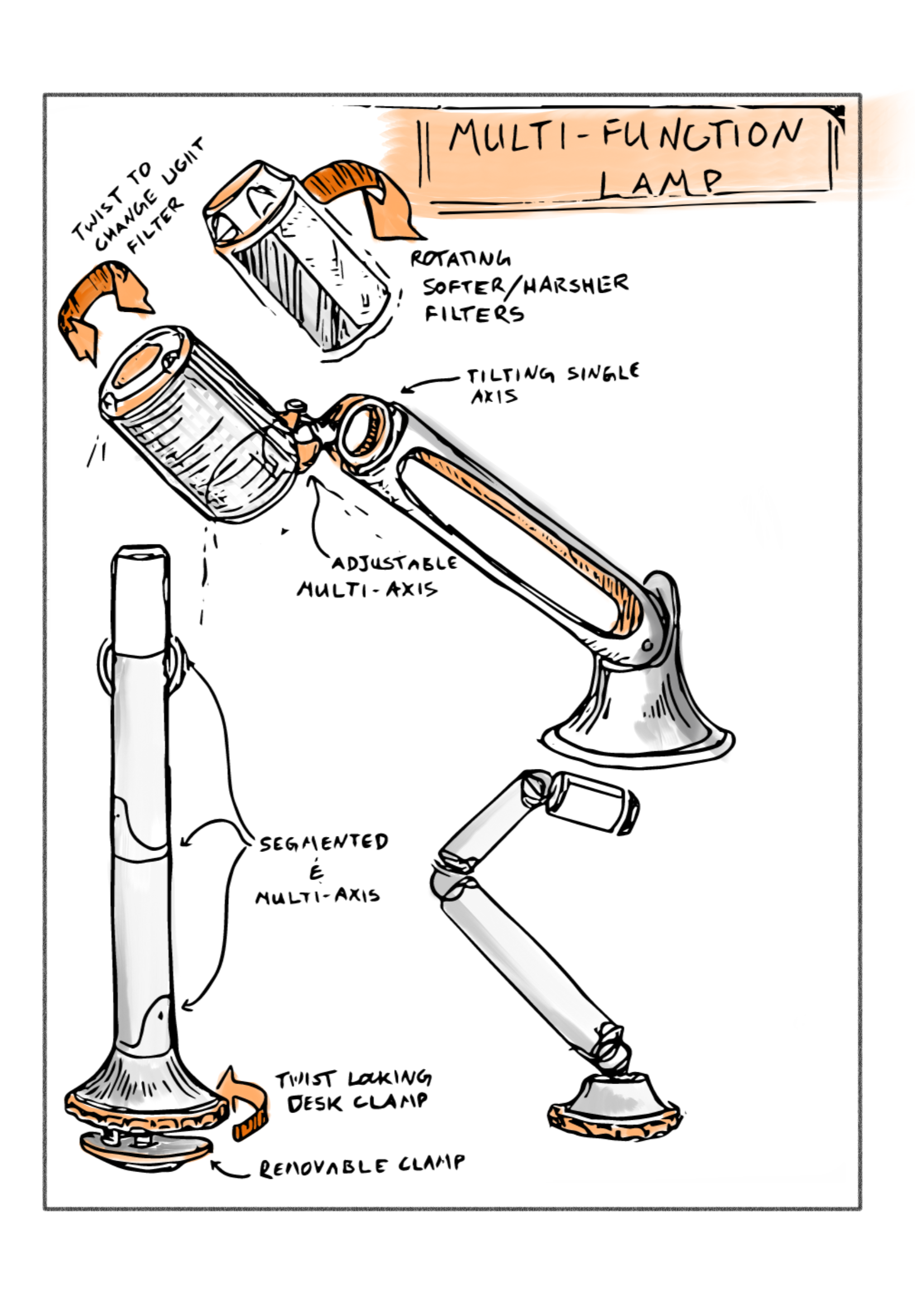

Concept and Industrial Design

Industrial design plays a crucial role in the product design process by ensuring that the product looks, feels, and weighs exactly as envisioned. It constitutes one of the two key components of the product design process. While industrial design focuses on the aesthetics of the product, engineering forms the second part of this process. For more complex products, mechanical engineering and electrical engineering services are especially critical to ensure manufacturability. A well-designed and engineered product helps to guarantee that each unit coming off the production line is flawless, devoid of defects, and most importantly, provides an intuitive, compelling, and effortless end-user experience.

Prototyping

Prototyping is an integral part of the agile development process, wherein a preliminary version of a product is created to gather customer feedback and gain insights on how to enhance and optimize the product to ensure its success in the market.

When we reflect on our own buying habits, we tend to be drawn towards products that possess an attractive appearance and judge their quality based on how they feel, their weight, and how effortless they are to use. As a result, inventors must apply the same rationale to their own products to provide the best possible experience for their customers. The success of a business is not solely determined by the inventor's perception of what is best, but rather by listening to the feedback of their customers - from major decisions like the speed of the product's functionality to smaller details like the choice of exterior material.

Manufacturing Consulting

Manufacturing involves the precise combination, shaping, forming, and assembly of machinery, raw materials, and components in accordance with the specific instructions and calculations provided in a CAD file, resulting in the creation of individual parts or an entire product.

Through the establishment of a global network of manufacturers and suppliers, we have been able to achieve several benefits, including reduced supply costs, quicker responses to fluctuations in the supply chain, and access to a directory of specialized manufacturers capable of producing high-quality, proprietary, and customized parts at a significantly lower cost. This applies not only to overseas production but also to manufacturing right here in the United States and Canada.

Mechanical Engineering

Mechanical engineering involves the calculation and consideration of various environmental factors, energy conversion, material properties, internal and external forces, and the manufacturing process to ensure the durability, mobility, and functionality of the final product and its parts.

Consider the products that you use on a daily basis - the smooth driving experience of a car, the convenience of heating up leftovers in a microwave, the thrill of riding a responsive and stable bike down a mountain, or the relief of cool air from an air conditioner on a hot summer day - all of these are made possible by the principles of mechanical engineering. This highlights the significance of mechanical design and engineering, which is the precise science required to build products that align with your vision and surpass your user's expectations. If your product involves moving parts or requires manufacturing, then enlisting the services of a mechanical engineer is crucial.

“Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution; it represents the wise choice of many alternatives.”

~William A. Foster